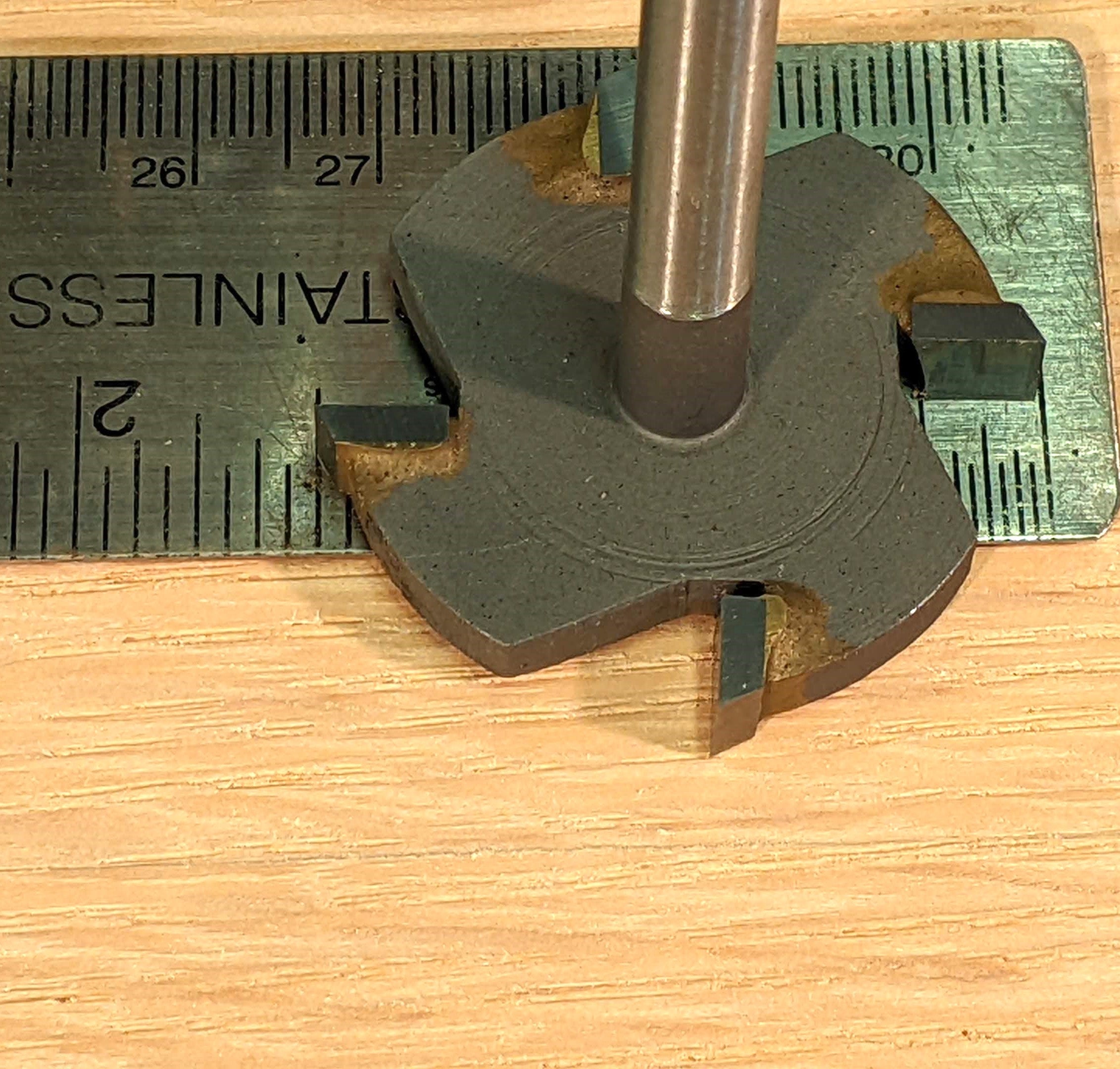

1.5" Surfacing Bit For CNC Router, Fast Spoilboard & Slab Flattenning, 1/4" Shank

Enhance Your Carve

1.5" Surfacing Bit For CNC Router, Fast Spoilboard & Slab Flattenning, 1/4" Shank

$42.65 USD

Add this item

+

High-Performance 1/4 Up Cut Endmill For CNC Routers, 1/4 Shank

$33.98 USD

Add this item

+

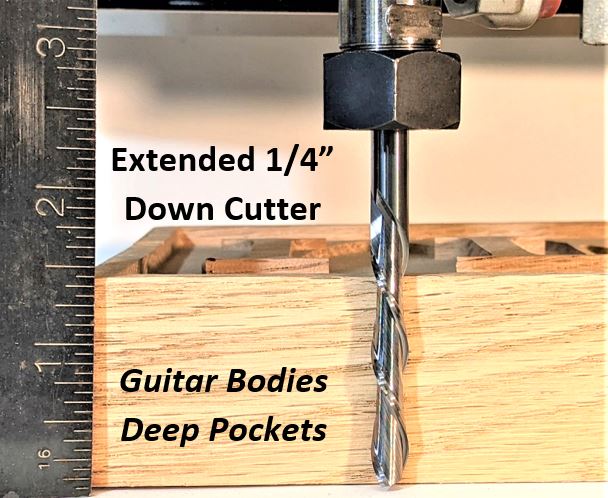

Long 1/4" Router Bit For CNC & Trim Routers, 1/4" Shank

$45.96 USD

Add this item

Key Details

Feeds And Speeds

Reviews

This 1-1/2 inch surfacing bit, designed for super-smooth cuts, is used in your CNC router to surface or flatten your CNC router spoilboard (also called a spoiler board, or waste board), as well as slab flattening, and prepping your CNC router project surfaces. The surfacing bit for CNC routers is a super-important bit to have.

The IDC Woodcraft 1.5 inch surfacing bit works with all brand CNC machines with a 1/4" collet.

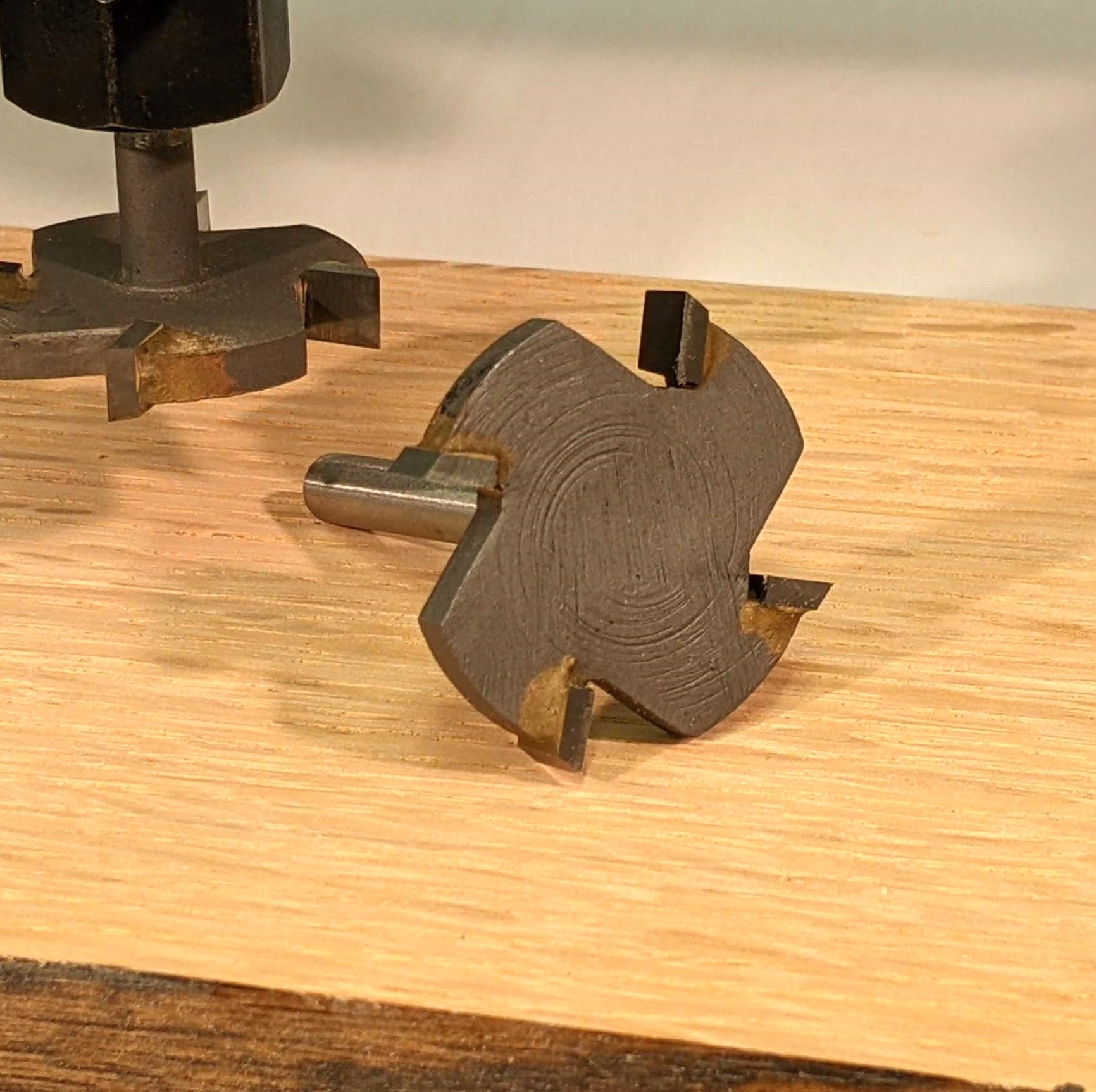

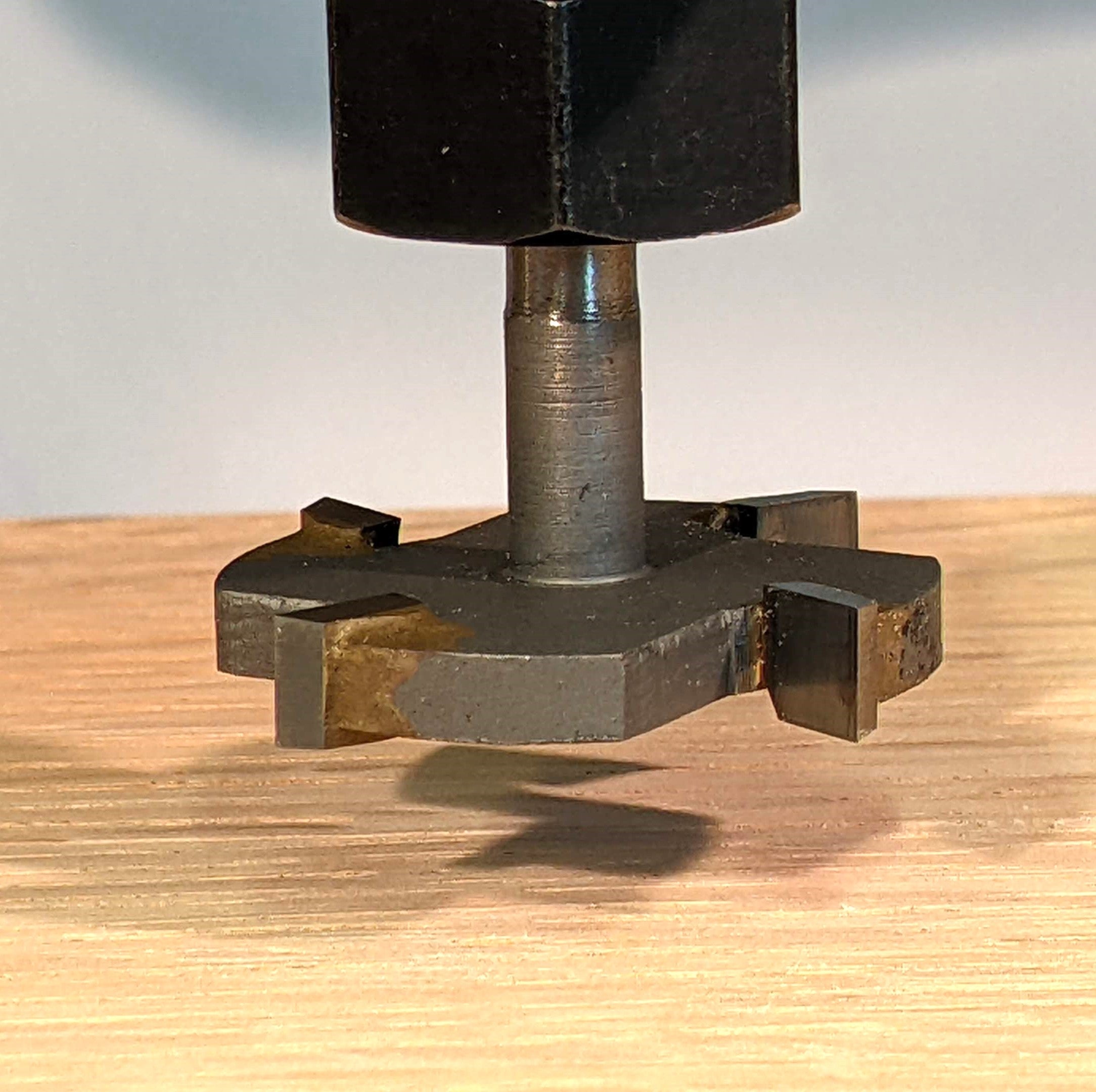

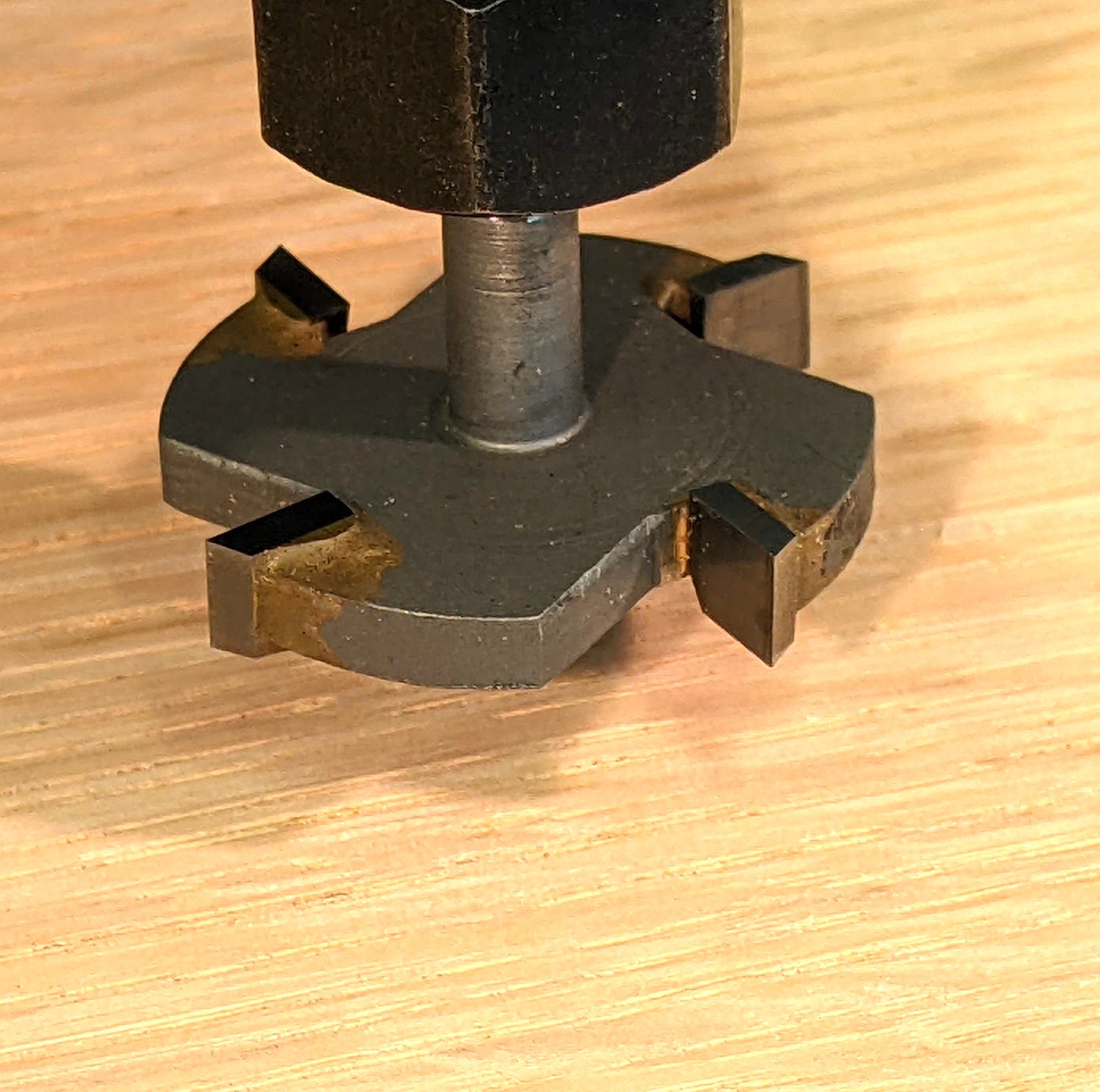

What makes the 1-1/2" surfacing different? Typical surfacing bits for CNC routers are 1" diameter. They work fine. However, they do take longer to do your surfacing work. With the 1-1/2 inch surfacing bit, and a stepover of 90%, the surface work can be done in half the time, and you'll have a much smoother finish due to the broad cutting area.

What's more significant is the 4-flute design. Most surfacing bits only have three flutes. This allows for better finishes with faster cutting speeds. And more flutes means extended tool life, as well.

This video shows this bit in action. Itis shown a few minutes into he video.

You'll find the surfacing bit is a necessary bit almost immediately after you get your CNC router. This is because most spoil boards (a.k.a waste board or spoiler board) are not parallel to the router motion. So you need a flattening bit to resurface it.

Receiving your new CNC router is exciting. One of the first tasks you will want to do is level up your spoilboard for 2 reasons.

- Your projects will cut even.

- You won't cut into your spoilboard at high spots.

Spoilboard resurfacing is actually a very common thing that has to be done with new CNC routers, as well and reconditioning the surface after it has been cut into many times.

This 1.5" diameter surfacing bit is made specifically for hobby and semi-professional CNC'ers. It is made to get effective clean-up on your spoilboard in one pass at high feed rates.

To read more about what a spoilboard is, read this article or watch this video about surfacing bit feeds and speeds, or this video about how a surfacing flattening bit can be used.

Use

- Spoilboard. or waste board leveling

- Spoilboard resurfacing

- Slab flattening

- Cleaning up warped project materials

Item SKU: SU-15

For Vectric users, get the latest CNC router bit tool database by going to this page

For CNC’s with routers, refer to this PDF download feeds & speeds table

Get feeds and speeds in your shop by scanning this QR code with the IDC Woodcraft App